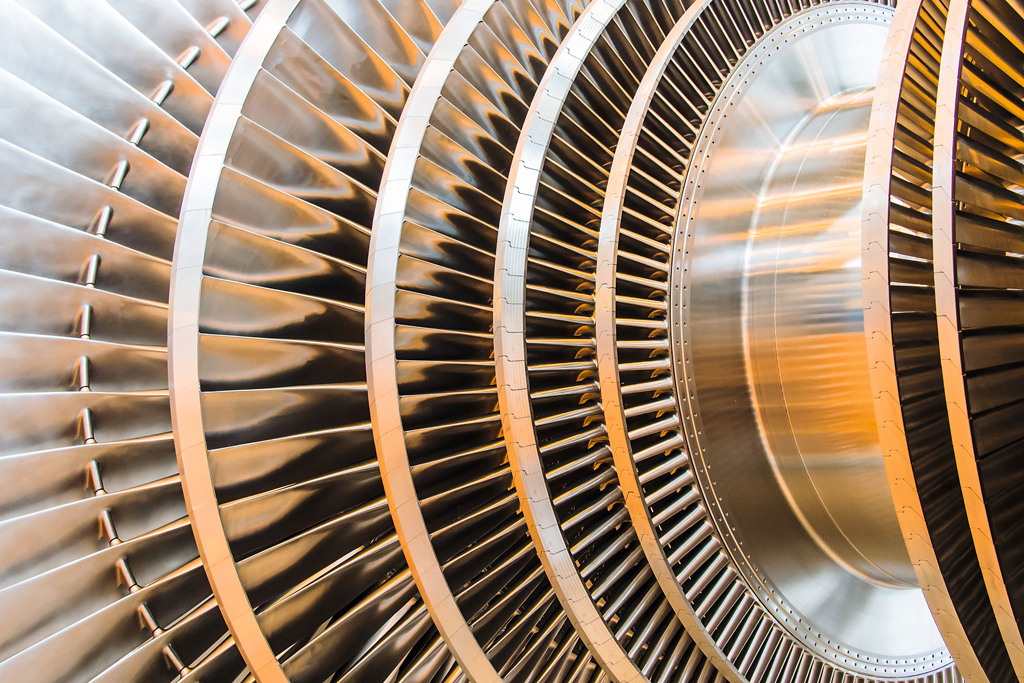

30 Nov Why Turbine Oil Maintenance is Important

Maintaining and analyzing turbine oil for your engine is an important process because it allows the engine to last longer and cuts down the cost for possible repairs. If your business operates on equipment that uses turbine oil, then this article is for you. We’ll be breaking down to you the importance of maintaining and analyzing turbine oil in engines.

Turbine oil has come a long way and the demands on its performance is increasing. The high demands are also equal to clean long lasting performance and it minimizes the cost in the long run.

What are the requirements of the usage of turbine oil?

Turbine oil has to be thermally stable and highly oxidative in order to be used in turbines. This is needed to endure the high operating temperature of the turbine system. Aside from that, the turbine oil that will be used must be free from any contamination to ensure durability and efficiency. Once it is contaminated, it can hinder the main functions of lubricating bearing and gears. And because of that, your turbine engine might be less-effective.

Did you know that the formation of sludge within the turbine system can have bad effects on your entire engine? For regular maintenance of the turbine oil, a regular testing should be done to make sure the increasing levels of oxidation are not present within the oil. With that, you can achieve a high operating turbine engine.

You might be wondering how does the maintenance of turbine oil work? Well, here is the answer… Different distributors give out different testing options and kits that lets the owner know the level of oxidation in turbine oils, detect the moisture content within the oil, and even analyze the particles of oil.

A few of the most common techniques when analyzing turbine oils are elemental analysis, measuring the water content in the oil and the viscosity at different temperatures, calculating the number of particles, particle size distribution within the oil, and measuring the oxidative stability of the oil using rotary pressure vessels.

There are many tests and techniques that can be used for quality control in order to help maintain the high efficiencies of the turbine engine. Aside from regular testing and maintenance, the key to a long-lasting turbine oil is choosing an oil which is highly oxidative and resistant to antioxidant aggregation. This is to keep your turbine engine smooth-running and efficient.

Need help on knowing what’s the best turbine oil for your engine? Contact our specialists today and we’d be glad to answer you!